Warehouse 9

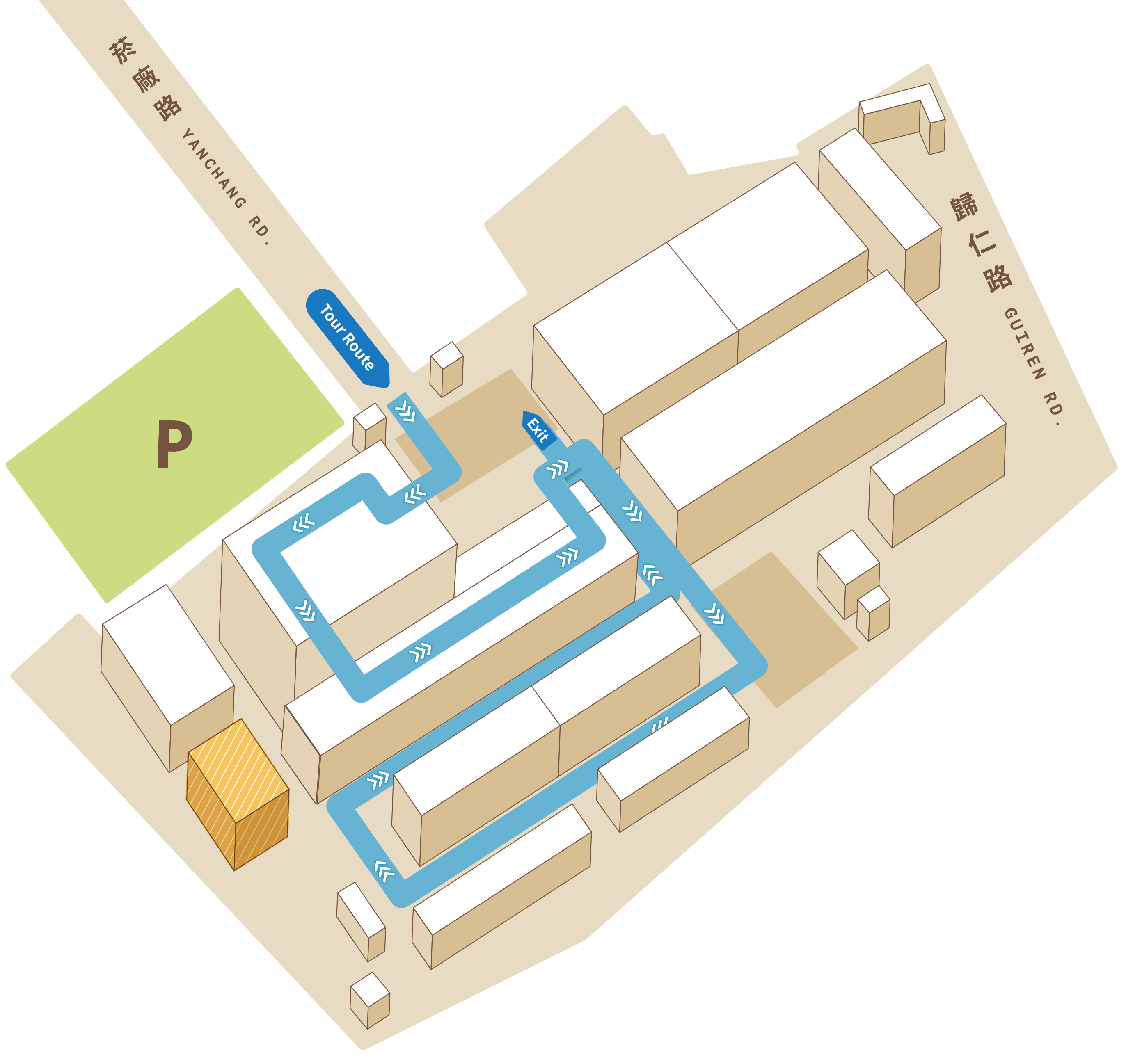

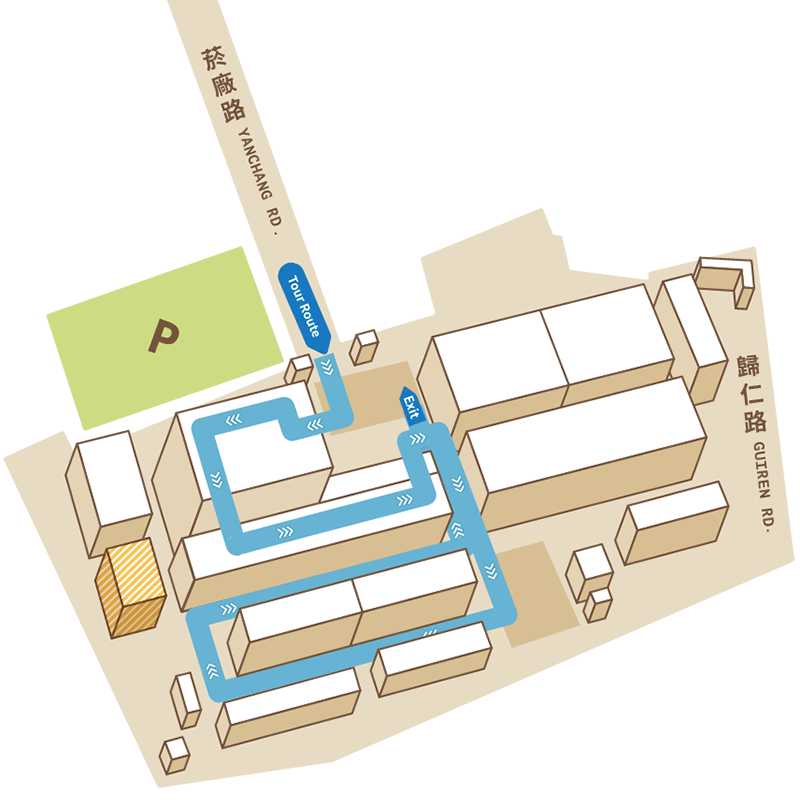

Factory Chief Director: As the tobacco factory has gradually automated and increased its production capacity, the processing finished tobacco leaves are usually kept in warehouses for two to three years for fermentation, thus increasing the need for warehouses. New warehouses have to be built in various corners of the factory in the future. The row in front of us is warehouse number 8 and 9, and behind it is warehouse number 10. These earlier warehouses are mostly for lower grade tobacco leaves or tobacco ribs. Other warehouses with numbers greater than 10 were built later, often with newer construction techniques and better storage features and were used mainly for higher grade tobacco.

Material Section Manager: We in the Materials Section are primarily responsible for the management of the warehouse. We have to keep an eye on the tobacco from after preliminary smoking after it enters the factory. Usually, the first floor of the warehouse is used to store tobacco after preliminary smoking or tobacco ready for export. Starting from the second floor, we store tobacco in different locations according to its grade, thickness, and year. We inspect the warehouse every day to record the temperature and humidity and to observe the number of eggs on the insect trap paper. When the temperature rises, the number of tobacco beetles usually soars and must be dealt with quickly. We also need to remove the lids regularly to check if the tobacco leaves are moldy and rotten. Tobacco leaves are barrels of gold to us, so of course, we must take good care of them.