Pingtung 1936 Tobacco Culture Base

Click the button above to play the audio tour

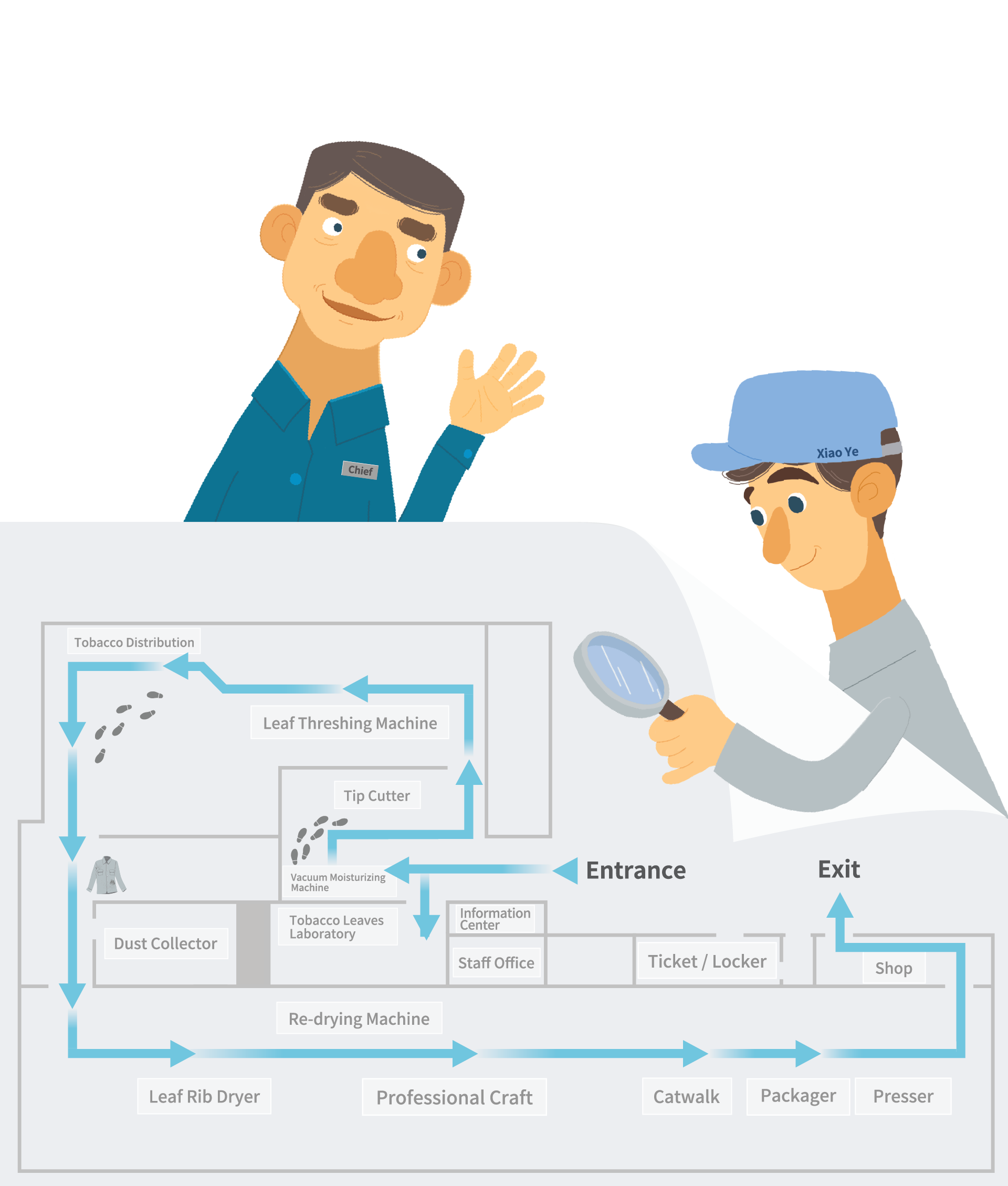

Factory Chief Director: Hello, welcome to Pingtung 1936 Tobacco Culture Base, I am the Chief Director of the Pingtung Tobacco Factory! During the period of Japanese rule, the tobacco monopoly system was implemented. This factory was built in 1936. We were responsible for buying raw tobacco leaves from the production areas, performing preliminary processing, and selling them to many overseas tobacco factories, as well as shipping them to the Shongshan Tobacco Factory in Taipei, which was responsible for producing American-style cigarettes. For the next 67 years, the tobacco factory supported the livelihoods of tobacco farmers’ families through instruction in farming techniques and the purchase of tobacco leaves. The surrounding residents came to work at the factory, bringing together the people of the area!

Under Japanese rule, Taiwan had five major tobacco production areas, namely Yilan, Taichung, Chiayi, Pingtung, and Hualien. In the 1970s, the number of tobacco fields in the Kaohsiung-Pingtung production area, known as the “Pingtung Tobacco Area,” increased to become the largest tobacco production area in Taiwan. However, since Taiwan opened up the import of foreign tobacco in 1987 and joined the World Trade Organization in 2002, the domestic tobacco industry gradually lost competitiveness when facing the low price competition from foreign tobacco industry. In addition, it is considered that smoking is harmful to health and the government’s anti-smoking policy led to a gradual decline in cigarette sales. The Pingtung Tobacco Factory also ceased operations in 2002 and entered history. In 2017, some important buildings in the factory were registered as historical buildings. After you hear the beep, I’ll take you back to the golden years of the Pingtung Tobacco Factory.

Material Section Manager: Chief, bad news. A batch of tobacco has disappeared from the warehouse!

Factory Chief Director: What! Let me think what we should do. By the way, I heard that you have a new employee, Xiao Ye who loves reading mystery novels and solving puzzles.

Material Section Manager: Yeah, he’s really good.

Factory Chief Director: Ask him to come to the tobacco lab and help, please.